add here text

What is an EV Motor Controller and Why Does It Matter?

pratik r. sonawane

June 07, 2025

related topics

⚡ Introduction: What is an EV Motor Controller and Why Does It Matter?

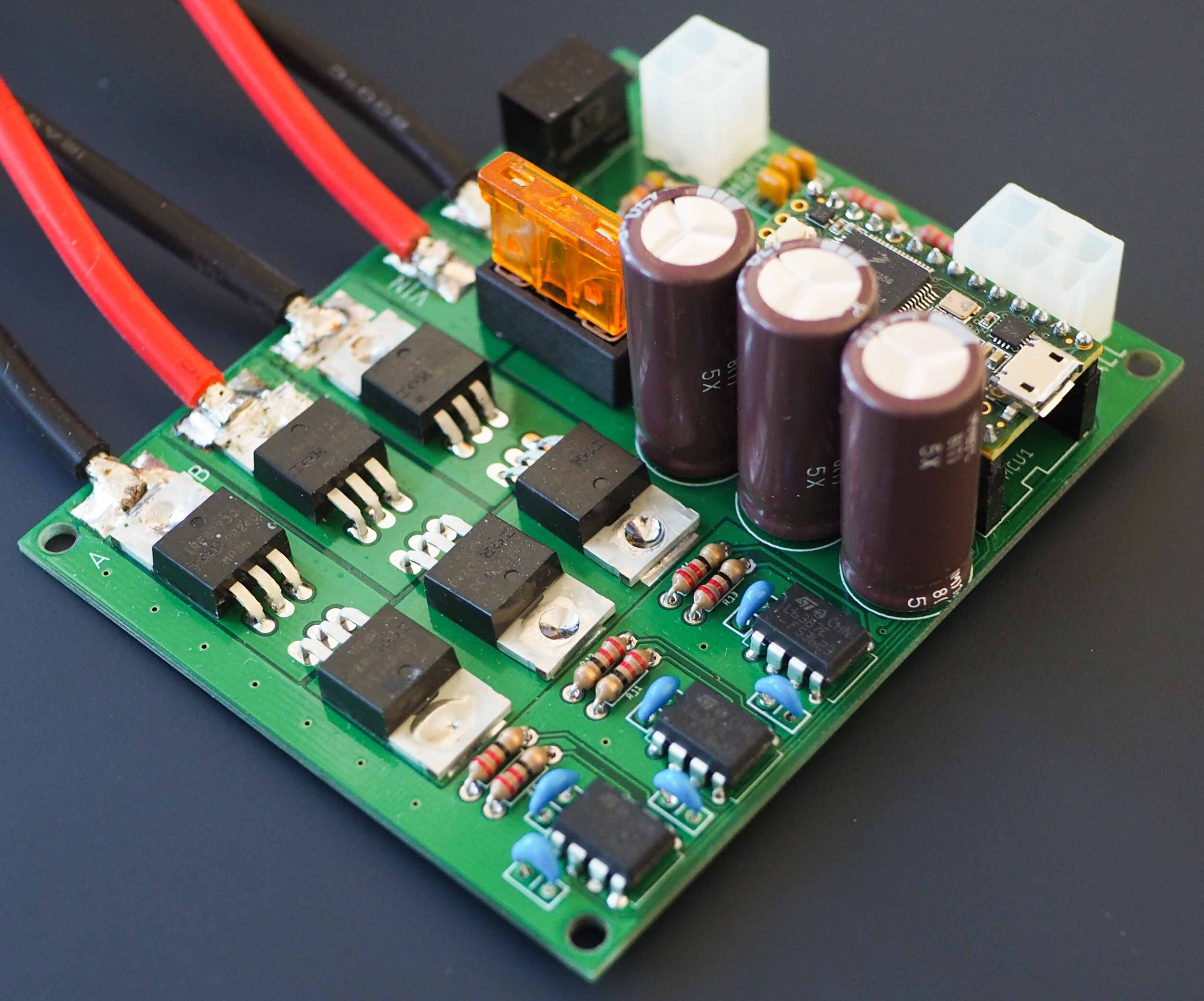

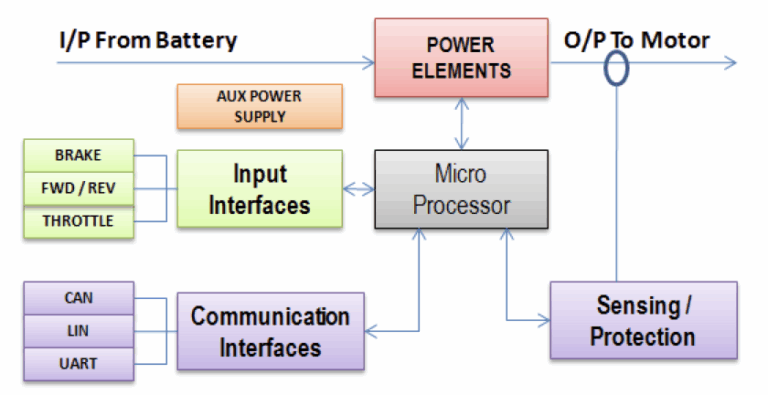

ectric vehicles (EVs) are revolutionizing transportation, but beyond batteries and motors lies a crucial component: the EV motor controller. This device controls how power flows from the battery to the motor, managing speed, torque, and regenerative braking.

Whether you’re an EV enthusiast or simply curious about how electric cars work, understanding the EV controller’s role is key to appreciating how these vehicles deliver smooth, efficient, and safe performance. In this article, we’ll explore how EV controllers operate and why they are essential for every electric vehicle on the road today.

🧾 Quick Summary:Understanding the Role of EV Controllers in Electric Vehicles

The EV motor controller is a vital electronic control unit that manages the efficient transfer of power from the high-voltage battery to the electric motor in electric vehicles (EVs). It processes critical inputs from the accelerator pedal, brake system, and motor sensors to regulate motor speed, torque, and power delivery using advanced control algorithms like Field-Oriented Control (FOC) and Pulse Width Modulation (PWM).

Equipped with a high-frequency inverter, the controller converts DC battery power into precise three-phase AC power, ensuring smooth and responsive motor operation. It also manages regenerative braking, capturing kinetic energy to recharge the battery and extend driving range. Continuous real-time monitoring and diagnostics safeguard against electrical faults, overheating, and system failures, guaranteeing reliable and safe EV performance.

Understanding the role of the EV motor controller is essential for anyone interested in electric vehicle technology, EV drivetrain efficiency, and the future of clean mobility.

🧠 What Is an EV Controller?

An EV controller is a power electronics device that acts as the interface between the battery and the electric motor. Its job is to control speed, torque, direction, and regenerative braking, while ensuring efficiency, safety, and responsiveness.

Converts DC battery power to 3-phase AC for the motor

Manages motor speed and torque

Handles real-time safety protections

Enables regenerative braking

Communicates with the vehicle’s battery management system (BMS) and central EC

⚙️ How It Works: Simplified Breakdown

1. Inputs from Driver and Vehicle Sensors

The EV controller continuously receives real-time data from various inputs:

Accelerator pedal position sensor: Indicates driver’s throttle demand.

Brake pedal sensor: Detects braking actions to enable regenerative braking.

Motor rotor position sensors (Hall effect or encoder): Provide precise rotor angle and speed for accurate motor control.

Battery Management System (BMS): Supplies battery voltage, current limits, temperature, and state-of-charge information.

Using these inputs, the controller determines the required motor torque and speed.

2. Signal Processing and Control Algorithm Execution

At its core, the controller uses a digital signal processor (DSP) or a high-speed microcontroller to execute control algorithms in real time. These include:

Pulse Width Modulation (PWM): Controls the switching of power transistors to regulate voltage and current supplied to the motor.

Field-Oriented Control (FOC): The preferred method in modern EVs, FOC decouples the motor current into two orthogonal components — the direct axis (flux) and quadrature axis (torque). This enables precise, smooth torque control, higher efficiency, and better dynamic response compared to traditional trapezoidal or sinusoidal control methods.

Trapezoidal and Sinusoidal Control: Simpler control schemes sometimes used in lower-cost or smaller motors like brushless DC (BLDC) motors.

The controller continuously calculates the required phase currents and switching patterns to meet driver commands while optimizing performance.

3. Power Conversion: DC to AC via Inverter

The controller contains a power inverter, typically composed of high-power MOSFETs or IGBTs, which converts the battery’s high-voltage DC into three-phase AC power required by the electric motor. Key aspects include:

Switching Frequency: Usually between 10 to 20 kHz, which affects efficiency and audible noise.

PWM Techniques: Generate controlled sinusoidal waveforms with precise voltage and frequency to control motor speed and torque.

Thermal Management: Power devices require cooling to handle high currents and maintain reliability.

This inverter stage is critical for translating the controller’s commands into motor rotation.

4. Regenerative Braking Control

When the driver lifts off the accelerator or applies the brakes, the controller reverses the motor operation to function as a generator. Key points:

Energy Recovery: Converts kinetic energy back into electrical energy, feeding it into the battery and improving overall vehicle range.

Power Regulation: The controller manages voltage and current to ensure battery safety, preventing overcharging or damage.

Brake Blending: Coordinates regenerative braking with mechanical brakes for smooth deceleration and optimal energy recovery.

Effective regen control enhances energy efficiency and reduces brake system wear.

5. Real-Time Monitoring and Safety Management

EV controllers incorporate comprehensive safety and diagnostic features, continuously monitoring:

Overcurrent and Short Circuit Protection: To avoid damage from electrical faults.

Thermal Sensors: Monitor motor and controller temperature to prevent overheating.

Battery Voltage and Current Limits: Ensures operations remain within safe battery parameters.

Motor Performance: Detects anomalies such as rotor stalls or abnormal vibrations.

Insulation and Ground Fault Detection: Critical for high-voltage safety compliance.

The controller can shut down or derate power delivery proactively to protect components and occupants.

🧰 Types of EV Motor Controllers

1. BLDC Controller (Brushless DC Motor)

Common in e-bikes, scooters, and light EVs

Uses trapezoidal or sinusoidal control

Cost-effective, compact

2. PMSM Controller (Permanent Magnet Synchronous Motor)

Found in most modern EVs (Tesla, BYD, Kia EV6)

Uses advanced FOC or vector control

High efficiency and performance

3. AC Induction Motor Controller

Used by early Tesla models

No permanent magnets

Less efficient but rugged and cost-effective

📈 Why EV Controllers Are Critical to Performance

A well-designed controller:

Increases driving range through energy efficiency

Enables smooth acceleration and torque response

Allows advanced features like regenerative braking, launch control, and traction control

Ensures battery and motor protection

🔮 Future Trends in EV Controller Technology

AI and Machine Learning for predictive control

SiC (Silicon Carbide) and GaN (Gallium Nitride) power devices for ultra-high efficiency

Modular controllers for autonomous EV platforms

Cloud-connected diagnostics and over-the-air (OTA) updates

🔎 EV Controller Architecture: Key Components

| Component | Function |

|---|---|

| Microcontroller / DSP | Runs motor control algorithms |

| Power Inverter | Switches DC to AC power |

| Gate Drivers | Controls MOSFETs/IGBTs switching |

| Current Sensors | Monitors phase current |

| Position Sensors | Tracks motor rotation (Hall, encoder) |

| Cooling Interface | Fan or liquid cooling control |

| CAN Bus Interface | Communicates with ECU/BMS |

🚀Conclusion: A Brighter Future for EV Services in India

Whether it’s a luxury electric sedan or a compact electric scooter, the motor controller is the key component that determines how smoothly and safely the vehicle moves. As EVs continue to evolve, so too will their controllers — becoming faster, smarter, and more efficient.

If you’re building, buying, or studying EVs, understanding the EV controller system is essential for appreciating how electric vehicles truly work.

❓ Frequently Asked Questions (FAQs)

While no special training is required, it's important to follow manufacturer guidelines for charging and maintenance to ensure longevity.

Regularly follow maintenance tips provided by the manufacturer, including proper charging and periodic checkups.

Currently, service centers are limited in rural and smaller towns, but the network is expanding.

about author

Share this article

subscribe for weekly updates

180 Comments

Современная ветеринарная клиника в Москве Опытные терапевты и диагносты всегда готовы, чтобы вернуть здоровье вашему питомцу. Мы используем инновационной аппаратурой для точной диагностики, в том числе полный чек-ап организма. Связаться с нами можно в любое удобное время, так как наша ветеринарная клиника всегда на связи. Поручите профилактику заболеваний команде профессионалов, ведь для нас здоровье животных — главный приоритет.

круглосуточная ветеринарная помощь [url=http://www.veterinar-na-dom-moskva-24.ru]https://veterinar-na-dom-moskva-24.ru/[/url]

Начало вакцинации обычно приходится на ранний возраст щенков и котят, пока действует материнский иммунитет. В ветеринарной клинике подскажут подходящий график, возможно потребуются несколько последовательных прививок. Затем следует поддерживающая вакцинация по установленному расписанию. Важно соблюдать сроки и регулярно приводить животное на осмотр.

выездная вакцинация животных [url=https://www.vakcinaciya-pitomcev-v-moskve.ru/]https://vakcinaciya-pitomcev-v-moskve.ru/[/url]

Прежде чем звонить в сервис, можно проверить несколько простых вещей, например, плотность закрытия дверцы или исправность электророзетки.

ремонт холодильников [url=master-remonta-holodilnikov-msk.ru]https://master-remonta-holodilnikov-msk.ru/[/url]

Раздел 3: Когда стоит вызвать мастера: DIY или Профессионал

ремонт холодильников на дому [url=https://www.master-remonta-holodilnikov-msk.ru]https://master-remonta-holodilnikov-msk.ru/[/url]

Для строительства уютного загородного жилья идеально подходит [url=https://karkasnye-doma-pod-klyuch7.ru]дома каркасные спб[/url].

Такие дома отличает лёгкость конструкции и экономичность использования материалов.

Правильная защита от влаги и качественный утеплитель продлевают срок службы дома.

Теплосбережение каркасных домов делает их выгодными в эксплуатации.

Соблюдение технологий и качественные материалы обеспечивают долгую службу и удобство дома.

Этот прибор гарантирует сохранность еды на продолжительный срок, оберегая её от порчи.

ремонт холодильников цены [url=https://www.remont-holodilnikov-v-moskve-nedorogo.ru]https://remont-holodilnikov-v-moskve-nedorogo.ru/[/url]

Несмотря на высокую надёжность, рано или поздно любой аппарат подвержен поломкам.

ремонт старых холодильников на дому [url=https://www.remont-holodilnikov-v-moskve-nedorogo.ru]https://remont-holodilnikov-v-moskve-nedorogo.ru/[/url]

Некоторые ситуации требуют немедленного реагирования и экстренного вызова сантехника.

услуги сантехника в москве на дом недорого [url=https://santehnik-na-dom-moskva-nedorogo.ru/]https://santehnik-na-dom-moskva-nedorogo.ru/[/url]

Каждый случай рассматривается индивидуально, чтобы предложить наиболее эффективное и экономичное решение.

вызвать слесаря сантехника на дом москва [url=https://vyzov-santehnika-na-dom-msk.ru/]https://vyzov-santehnika-na-dom-msk.ru/[/url]

Наличие гарантии на услуги, использование спецтехники и следование всем требованиям – залог надежного сервиса.

сантехник москва вызов [url=http://www.vyzov-santehnika-na-dom-msk.ru]https://vyzov-santehnika-na-dom-msk.ru/[/url]

Ответственная организация или частный предприниматель всегда открыто сообщат о своих услугах и прейскуранте.

электрик на дом москва цены [url=https://www.vyzov-elektrika-na-dom-msk.ru]https://vyzov-elektrika-na-dom-msk.ru/[/url]

Также рекомендуется проводить профилактическую чистку от накипи с помощью специальных средств или лимонной кислоты.

ремонт стиральных машин выезд [url=https://www.master-remonta-stiralok-moskva.ru]https://master-remonta-stiralok-moskva.ru/[/url]

Квалифицированный мастер точно определит причину поломки и заменит дефектные компоненты на подлинные или качественные аналоги.

вызов мастера по стиральным машинам [url=http://www.master-remonta-stiralok-moskva.ru/]https://master-remonta-stiralok-moskva.ru/[/url]

Ремонт стиральных машин: комплексный подход к восстановлению техники.

При наличии действующей гарантии на устройство обращение к специалисту является обязательным.

мастер ремонт стиральных машин [url=https://www.remont-stiralnyh-mashin-v-msk.ru]https://remont-stiralnyh-mashin-v-msk.ru/[/url]

ветеринар на дом вакцинация [url=http://www.privivki-dlya-zhivotnyh-moskva.ru/]https://privivki-dlya-zhivotnyh-moskva.ru/[/url]

вакцинация животных на дому [url=https://privivki-dlya-zhivotnyh-moskva.ru]https://privivki-dlya-zhivotnyh-moskva.ru/[/url]

Если вы готовите поездку между Берлином и Польшей, целесообразно знать отдаление и возможности добраться. Так, познань берлин расстояние насчитывает около 270 км, а попасть можно поездом, что легко и оперативно. К тому же многие интересуются, как достичь из берлина в потсдам или как переместиться до берлин-бранденбург аэропорт — есть ряд способов, с учетом поезд и автобус.

Для любителей истории следует осмотреть берлинский дворец или усадьбы в окрестностях берлина, а если необходимо больше материалов о направлениях и доставке, подсказываю ознакомиться с [url=https://holidaygid6.ru]берлин замок[/url] . Коли вам надо добраться из аэропорта берлина до автовокзала или выяснить сведения про поезда днепр-берлин или ужгород-берлин поезд, на платформе часто разбирают такие трассы и делятся актуальные консультации.

Если вы мечтаете о надежном и теплом жилье, обратите внимание на [url=https://karkasnye-doma-pod-klyuch7.ru]каркасный дом под ключ в спб[/url], которые сочетают качество, скорость возведения и доступную стоимость.

Каркасные дома стремительно завоевывают популярность среди застройщиков.

Если вы ищете профессиональный [url=https://deteiling-dlya-vas.ru]детейлинг кузова[/url], мы готовы предложить вам качественные услуги и индивидуальный подход.

Обращение в детейлинг центр приносит множество выгод собственникам автомобилей.

Если вы хотите [url=https://3-d-zabor.ru]купить забор 3д от производителя в москве[/url], обращайтесь к нам для выгодных условий и высокого качества.

Покупка забора 3Д у производителя гарантирует, что изделие соответствует нормативам и прослужит долгие годы.

Для безопасной игры и получения бонусов посетите [url=https://fugucasino01.online/]вывод с фугу казино[/url].

Сайт остаётся одним из лидеров в области онлайн-развлечений благодаря вниманию к клиентам.

Для безопасной игры и получения бонусов посетите [url=https://fugucasino01.online/]fugu casino приложение[/url].

Сайт предоставляет широкий выбор развлечений с привлекательной графикой и быстрыми выплатами.

Discover the thrill of the aviator game at [url=https://online-aviatorgame.com/]inverter game[/url], where precision and luck collide in the sky.

Learning through observation, players can detect patterns in how often cash-outs occur and plan accordingly.

Scopri l’emozione di Crazy Time Casino Slot Italy con l’opzione [url=https://crazy-time9.com/]live crazy time[/url] e vivi una partita piena di colpi di scena.

Infine, mantenere una routine di gioco responsabile permette di godere dell’esperienza senza rischi eccessivi, sfruttando al meglio le funzionalita di Crazy Time Slot Italy.

crazy time simulator [url=https://www.crazy-time9.com/]https://crazy-time9.com/[/url]

تُثري العروض الترويجية تجربة اللعب وتساعد اللاعبين على زيادة فرص الفوز

starz888 [url=https://888starz-eg-egypt.com]https://888starz-eg-egypt.com/[/url]

Wskazywane sa takze praktyczne porady, jak maksymalnie wykorzystac bonusy i uniknac typowych problemow.

vulkanspiele kod promocyjny [url=inscada.ru/vulkanspiele-kod-promocyjny-jak-uzyska-bonus-powitalny-bez-b-d-w]https://inscada.ru/vulkanspiele-kod-promocyjny-jak-uzyska-bonus-powitalny-bez-b-d-w/[/url]

Vulkan Vegas offers exciting no deposit codes and bonus options, including free spins and deposit bonus codes, designed to boost your gaming experience without an upfront deposit.

Engaging with the casino’s updates ensures you don’t miss upcoming no deposit promotions

Redeeming a no deposit code typically starts on the promotions page or the cashier area of Vulkan Vegas. The process is usually straightforward: enter the code in a dedicated field and claim the bonus. Next, you may need to verify your account or meet simple eligibility requirements before the bonus appears in your balance. Then, you can begin playing eligible games, often with a capped maximum bet and wagering requirements to clear the bonus. Finally, track your progress in the promotions tab to know when you’ve met the wagering obligations.

Keep track of any wagering requirements and eligible games listed in the terms

vulkan vegas casino no deposit bonus [url=https://www.vulkan-vegas.nz/no-deposit-bonus]https://vulkan-vegas.nz/no-deposit-bonus/[/url]

Bezpieczenstwo i uczciwosc to key elementy, ktore winny byc brane pod uwage , decydujac sie na gre . Szanse w vulkanspiele moga byc korzystne , ale uczestniczyc z glowa.

vulkanspiele casino online [url=https://vulkan-spiele4.com/]vulkanspiele casino online[/url].

Discover the excitement and win big with exclusive bonuses at [url=https://fairspin-casino.com/]fairspin[/url].

Users can fund their accounts via cryptocurrencies as well as traditional payment systems.

Znajdziemy tam szeroki wybor roznorodnych tytulow, ktore przyciagaja uwage graczy.

vulkanspiele kod promocyjny [url=https://newwallcovering.com/vulkanspiele-kod-promocyjny-jak-odebrac-bonus-bezpiecznie-i-bez-pomylek/]https://newwallcovering.com/vulkanspiele-kod-promocyjny-jak-odebrac-bonus-bezpiecznie-i-bez-pomylek/[/url]

В Москве существует множество автосервисов, специализирующихся на Тойота. Профессионалы помогут вам с ремонтом и техническим обслуживанием.

Если вам нужен качественный и надежный [url=https://servis-toyota-moskva.ru/remont-toyota-v-moskve/] автосервис Toyota в Москве[/url], мы предлагаем широкий спектр услуг для вашего автомобиля.

Ремонт и обслуживание Тойота требуют от специалистов глубоких знаний. Мастера сервиса постоянно повышают свою квалификацию для качественного обслуживания.

В автосервисе установлено современное оборудование. Благодаря этому, мы можем гарантировать качество выполняемых работ.

Наш автосервис обеспечивает надежность и долговечность вашего автомобиля. Ваше доверие для нас — наивысшая награда.

Discover the thrill of online gaming at [url=https://777-bet.io/]777bet casino[/url], where exciting bets and big wins await you!

Welcome bonuses are commonly offered to new users to increase their first deposits.

Discover the excitement and top bonuses at [url=https://66exbet.com/]ExBet Casino[/url], your ultimate destination for online gaming.

Users benefit from an intuitive interface combined with powerful analytics designed to optimize their betting activities.

Experience thrilling wins and endless entertainment at [url=https://777bet-registration.com/]777 bet Casino[/url], your ultimate destination for online gaming.

Among various online betting platforms, 777bet has become increasingly favored by bettors worldwide.

Если вы ищете портативное и качественное решение для записи звука, обратите внимание на [url=https://rode-wireless-pro.ru]система RODE Wireless PRO[/url].

Данная особенность незаменима при выездных съемках и мероприятиях.

Закажите кровать на заказ у наших мастеров: [url=https://krovat-na-zakaz.ru/]купить кровать с доставкой в москве[/url].

Опытные специалисты внимательно работают над каждым заказом, учитывая индивидуальные требования.

Перспективы ай-тек предполагают появление революционных решений и усовершенствований.

айтек [url=http://www.i-tec.ru]https://i-tec.ru/[/url]

Если вы мечтаете о [url=https://karkasnye-doma-pod-klyuch7.ru]каркасных домах в спб[/url], мы готовы помочь воплотить эту мечту в реальность!

Раздел 2. Проект и подбор материалов для каркасного дома.

Если вам необходима [url=https://arenda-avtomobilya-s-voditelem2.ru/]авто с водителем новосибирск[/url], то наши предложения по аренде авто с водителем в Новосибирске идеально подойдут для комфортных поездок.

Заказать авто с водителем в Новосибирске — отличный способ передвигаться быстро и удобно.

Такая услуга пользуется популярностью среди бизнесменов и туристов, которые хотят сэкономить время.

Обязательно обратите внимание на тарифы и дополнительные услуги, предлагаемые компанией по аренде авто с водителем.

Выбор компании для аренды авто с водителем в Новосибирске зависит от бюджета и личных предпочтений клиента.

Заказать авто с водителем можно как на несколько часов, так и на целый день, в зависимости от потребностей клиента.

Для бронирования автомобиля с водителем достаточно связаться по телефону или через онлайн-форму на сайте.

Обратившись к профессионалам, вы получите комфорт, экономию времени и спокойствие во время путешествия.

Experience the thrill of online gaming at [url=https://site-777bet.com/]777bet casino[/url], where excitement and big wins await you.

Another advantage of 777bet is its mobile compatibility.

—

With mobile access, placing bets becomes convenient regardless of location.

Discover endless fun and excitement at [url=https://gooday4play.com/]good day 4 play[/url], your ultimate destination for entertainment.

Such harmony can result in increased contentment in daily tasks and free time.

Если вы ищете надежный [url=https://graviynyy-velosiped.ru/]купить гравийный велосипед в москве[/url], у нас вы найдете лучшие предложения и доступные цены.

Конструкция гравийного велосипеда отличается усиленной рамой и широкой резиной.

Для надежной и стильной защиты вашего дома выбирайте [url=https://avtomaticheskiye-vorota.ru/]откатные ворота цена с установкой[/url] — это идеальное сочетание качества и элегантности для вашего участка.

Кованые откатные ворота представляют собой сочетание красоты и надежности.

Discover the excitement of online gaming with [url=https://exbet-login.com/]exbet app[/url], your ultimate destination for thrilling bets and big wins.

It is important to grasp what an ex bet entails before engaging in betting activities.

Если вы хотите [url=https://kupit-letnie-shini1.ru/]купить колеса лето[/url], то у нас вы найдете лучшие предложения и выгодные цены.

Размеры шин должны строго соответствовать рекомендациям производителя автомобиля.

Если вы мечтаете о надежном и уютном жилье, обратите внимание на [url=https://karkasnye-doma05.ru]каркасные дома под ключ в спб цены[/url], который сочетает в себе качество, современный дизайн и доступную стоимость.

Основой каркасного дома является прочный каркас из древесины или металла.

Discover the easiest way to create your custom impression with our [url=https://stamp1-creator1.com/]make stamp online free[/url]—fast, efficient, and user-friendly.

These platforms allow users to customize their stamps with various designs and fonts. Consequently, users enjoy the benefit of designing and ordering stamps remotely.

Moreover, the digital approach to stamp making saves valuable time. The entire process, from crafting to dispatch, is managed efficiently online. Customers appreciate the hassle-free experience of receiving their stamps quickly and accurately. Factors such as product durability, speed of delivery, and support quality should be prioritized. Reviewing user feedback and ratings can reveal trustworthy vendors.

Lastly, affordability often plays a major role in decision-making. Many companies offer competitive rates without sacrificing quality. Discounts and bulk order promotions further enhance purchasing value. The optimal rubber stamp purchase involves a harmonious combination of these factors.

L’aumento della popolarita dei giochi d’azzardo online in Italia e stato notevole, con molti giocatori che cercano di vincere grandi somme di denaro . Uno dei giochi piu popolari e il Crazy Time Casino Slot, che offre un’esperienza unica e emozionante ai giocatori. Il Crazy Time Casino Slot e un gioco molto popolare, che offre un’esperienza unica e emozionante ai giocatori. I giocatori possono partecipare a questo gioco da casa propria, utilizzando un computer o un dispositivo mobile. I giocatori possono giocare a questo gioco da casa, utilizzando un computer o un dispositivo mobile .

Il Crazy Time Casino Slot e un gioco molto semplice da giocare, ma richiede una strategia per vincere grandi somme di denaro. Il Crazy Time Casino Slot e un gioco molto semplice da giocare, ma richiede una strategia per vincere grandi somme di denaro . I giocatori devono scegliere la loro scommessa iniziale e poi attendere il risultato della ruota. I giocatori devono selezionare la loro scommessa iniziale e poi aspettare il risultato della ruota . Il gioco offre anche una varieta di funzioni bonus, come il gioco della ruota e il gioco dei dadi. Il gioco offre anche una varieta di funzioni bonus, come il gioco della ruota e il gioco dei dadi .

crazy time oggi [url=https://crazy-time3.com/]https://crazy-time3.com/[/url]

Warm greetings! Hope you’re doing well.

I’m in a position to help people financially with their endeavors and personal challenges. If this is you, get in touch via WhatsApp +66993739062

Ремонт пылесосов Dyson включает в себя комплекс мер по устранению поломок. Ремонт таких устройств может показаться сложным, но с правильным подходом и знаниями можно добиться отличных результатов. Определение неисправностей в пылесосах Dyson требует специальных инструментов и оборудования. Это шаг, который нельзя пропустить, поскольку он напрямую влияет на эффективность последующих действий.

Правильный ремонт пылесосов Dyson обеспечивает их долгую службу и высокое качество уборки . Кроме того, ремонт позволяет снизить затраты на приобретение нового оборудования и сократить время простоя устройств. Самостоятельный ремонт пылесосов Dyson требует определенных навыков и знаний .

Основные поломки и их устранение

Наиболее частыми поломками в пылесосах Dyson являются засоры и неисправности двигателя . Для их устранения необходимы определенные инструменты и знания. Устранение засоров в пылесосах Dyson включает в себя осмотр и очистку воздушных каналов . Это позволяет вернуть пылесосу его прежнюю производительность и качество уборки.

Проверка и очистка фильтров, а также замена изношенных деталей являются важными шагами . Правильное хранение пылесоса и его аксессуаров также является важным аспектом предотвращения поломок. Это не только экономит время и деньги, но и обеспечивает безопасность использования устройства.

Инструменты и материалы для ремонта

В их число входят наборы отверток, ключи и другие инструменты для разборки и сборки устройства . Альтернативные материалы и инструменты также могут быть использованы, но их качество должно соответствовать оригиналу. Это позволяет обеспечить долгую службу и высокое качество работы пылесоса после ремонта.

Ремонт пылесосов Dyson также требует определенных знаний и навыков . Курсы и тренинги по ремонту также могут быть полезны для приобретения необходимых навыков . Это позволяет пользователям стать более независимыми и способными выполнять ремонт самостоятельно.

Использование качественных материалов и инструментов также имеет важное значение для долгой службы пылесоса. Развитие технологий также будет влиять на то, как выполняется ремонт пылесосов. Это означает, что пользователям и профессионалам необходимо быть готовыми к новым вызовам и развивать свои навыки и знания.

Перспективы ремонта пылесосов Dyson включают в себя использование новых материалов и технологий . Разработка новых методов и инструментов для ремонта также будет иметь важное значение для обеспечения высокого качества работы устройств. Это позволит обеспечить еще более качественную и эффективную уборку с помощью пылесосов Dyson в будущем.

ремонт пылесосов дайсон в москве [url=dyson-service-center-msk.ru]https://dyson-service-center-msk.ru/[/url]

Dive into the world of online entertainment with [url=https://www.365-cuci.com/]365cuci casino[/url] and discover new possibilities today!

365cuci provides a convenient laundry service for everyday needs.

Clients take care of laundry without the need to go out.

Advanced logistics support smooth and reliable laundry service.

It is well suited for people with packed schedules.

Personal laundry preferences are easy to manage within the app.

The app also features transparent pricing and real-time order tracking.

Visit https://www.365-cuci.com/.

There are no easy answers in this war. Every victory comes with a heavy cost. The Onyx Storm epub documents the price of freedom. The characters are pushed to their breaking points. The ebook version is perfect for reading on the commute or in bed. It is a gritty, realistic take on fantasy warfare.

Food is a constant obsession in the book, representing both survival and control. The descriptions of hunger in District 12 versus the gluttony in the Capitol are powerful thematic elements. Collins uses food to symbolize power dynamics. To fully grasp these metaphors, a close reading of the text is recommended. Digital editions, such as a PDF, allow students and book clubs to easily navigate to these descriptive passages and discuss the symbolism of bread and the tesserae system.

The secrets of the revolution are finally being exposed, and the fallout is catastrophic. Violet is caught in the middle of a political storm that threatens to tear the kingdom apart. Reading the Onyx Storm epub is the best way to keep up with the fast-paced developments. The lore is dense but rewarding for those who pay attention. The digital book offers the flexibility to read anywhere, ensuring you never miss a beat of the action.

Для максимального комфорта и безопасности вашего жилья рекомендуем [url=https://automyhome.ru]Заказать систему умный дом в Санкт-Петербурге[/url].

Все больше жителей столиц выбирают умный дом для повышения качества жизни.

The Horizon Walker Ranger and the Monster Slayer are just two examples of how this book revitalizes the Ranger class. Xanathar’s Guide to Everything addresses many community complaints by offering potent new paths for every class. If you are looking for a digital PDF reference to build a stronger Ranger, our site provides the tactical advice you need. We break down the features level by level, showing you how to maximize damage and utility. Do not let your character fall behind in power; utilize the expanded options to become a true force of nature on the battlefield.

There is no safety in the skies anymore. The aerial combat scenes are written with a kinetic energy that makes your heart race. The Onyx Storm epub captures this energy perfectly on the digital page. Violet and Xaden must navigate trust issues while fighting a war they are losing. It is a compelling narrative of love and war. The ebook is the perfect solution for readers who want to save shelf space but still experience the epic scale of the story. https://onyxstormepub.ru/ Onyx Storm Pdf Drive

Every year, the Games remind the districts of their defeat. It is a ritual of humiliation. The book explores the psychological impact of this generational trauma. It is a heavy but necessary theme. To understand the anger of the districts, you must read the text. A PDF copy is a convenient way to access this powerful story, allowing you to reflect on the themes of oppression and resilience that define the series. https://thehungergamespdf.ru/ The Hunger Games Pdf Download Free

For those who love the forced proximity trope, this book delivers on every level. Dante and Vivian are forced to present a united front to the world while fighting a war behind closed doors. The search for a King of Wrath PDF often leads readers to discover a community of fans who adore the complexity of these characters. It is not just about the spice, although there is plenty of that; it is about the vulnerability that slowly emerges. Watch as the walls around Dante’s heart come crashing down in the most spectacular way possible. https://kingofwrathpdf.ru/ King Of Wrath Pdf Reddit

For the Sorcerer who wants to manipulate the fabric of reality, the Shadow Magic origin is terrifyingly effective. Xanathar’s Guide to Everything lets you survive death and summon hounds of ill omen. If you are hunting for a PDF guide on the Shadow Sorcerer’s quirks, our dark magic spotlights are perfect for you. We discuss how to use the “Darkness” spell effectively without blinding your own party. Embrace the gloom and become a master of the dark arts with this chilling subclass option. https://xanatharsguidetoeverythingpdf.ru/ Crime D&D 5E Xanathar’s Guide To Everything Pdf

The sheer scale of the conflict in this book is breathtaking. Armies are moving, wards are failing, and dragons are dying. It is a brutal, beautiful story that demands to be read. The Onyx Storm epub is available for those who prefer the modern convenience of digital reading. You will find yourself gasping at the twists and crying at the losses. The author has a gift for making you care deeply about every member of the squad. This isn’t just a book; it is an experience that is best enjoyed with a fully charged e-reader and no distractions. https://onyxstormepub.ru/ Onyx Storm Filetype:pdf

The frantic race to the Cornucopia to grab supplies is a masterclass in action writing. Every second counts, and one wrong move means death. The adrenaline rush of reading this scene is undeniable. Collins puts you right inside Katniss’s head. For action fans, this book delivers. If you want to read it on the go, searching for a The Hunger Games pdf is a great option to have the book accessible on your phone during your daily commute. https://thehungergamespdf.ru/ Read The Hunger Games Mockingjay Online Pdf

?????? 888starz casino ?? ??? ???? ??????????? ???? ???? ????? ???? prostrednictvim ???????? ? ??? ????? ??????? ??????? ??? ???????? ????????? ?????????? ??? ?? ????. ????? ??? ?????? ????? ??????? ?? ??????? ???? ??????? ??????? ? ??? ?? ??? ??????? ???????? ?????? ???? ?????? ??????. ????? ????? ????? ?? 888starz casino ????? ????? ?????? ? ??? ???? ???????? ??????? ?? ???????? ??????? ?????? ????? ???????? ???????.

?????? 888starz casino ?? ??????????? ???????? ???secure ? ??? ????? ????? ????? ?????? ???? ??? ??? ???? ??????. ?????? ??????? ?? d?i ???? ??????? ??? ?????? ?? ?????? ?????????? ? ??? ??? ????? ???? ??????????? ???????? ????? ???????. ????? ????? ????? ?? 888starz casino ????? ????? ?????? ? ??? ???? ???????? ????? ????? ???????? ??????? ???????? ?? ???????? ???????.

888star [url=888starzegypt2026.com]https://888starzegypt2026.com/[/url]

The third book is often the hardest to write, but this one feels effortless in its execution. The plot moves forward with purpose, resolving old mysteries while creating new ones. If you are hunting for the Onyx Storm epub, you are about to embark on an emotional rollercoaster. The dragons are as sarcastic and terrifying as ever. The digital edition is perfect for those who want to zoom in on the maps or adjust the text size for easier reading. It is a fantastic addition to any digital fantasy collection. https://onyxstormepub.ru/ Onyx Storm Full Book Pdf Download

Literature has the power to change how we view the world, and few books accomplish this as effectively as Orwell’s satire. The gradual alteration of history by the ruling class is a terrifying concept that is explored with masterful subtlety. Whether you are reading a physical copy or scrolling through an Animal Farm PDF on your phone, the impact of the ending is undeniable. The blurring lines between the pigs and the humans serve as a grim reminder that power tends to corrupt, and absolute power corrupts absolutely.

The Adventures of Tom Sawyer is a book that captures the essence of American youth. Mark Twain’s writing is brilliant and engaging. We offer a high-quality digital text for those who want to read the book on their devices. Our resource is designed to be easy to use. With a Tom Sawyer PDF, you can take the story with you on your travels or simply enjoy it at home, making classic literature more accessible than ever.

Il Crazy Time Casino Slot e un’esperienza unica nel suo genere.

La sua popolarita e dovuta alla sua semplicita e alla grande varieta di opzioni di scommessa disponibili. Il gioco e basato sulla fortuna, ma anche sulla scelta delle opzioni giuste.

Inoltre, il gioco offre una grande varieta di premi e bonus, che possono essere vinti grazie alle diverse combinazioni di simboli. I premi possono variare da pochi euro a somme molto piu consistenti .

joker crazy time [url=https://fnanbusinessdirectory.org/crazy-time-casino-live-italia-gioca-online-con-soldi-veri-e-diretta/]https://fnanbusinessdirectory.org/crazy-time-casino-live-italia-gioca-online-con-soldi-veri-e-diretta/[/url]

There are few books as universally recognized and loved as The Adventures of Tom Sawyer. It is a story that appeals to the adventurer in all of us. Our site makes it simple to obtain the full text for your personal use. If you appreciate the convenience of reading on a tablet, our digital edition is perfect. By downloading the Tom Sawyer PDF, you ensure that you have a permanent copy of this literary gem, free from the wear and tear of physical pages.

Acererak challenges you! Tomb of Annihilation is the ultimate test for 5th Edition players. The Tomb of Annihilation PDF is the DM’s playbook. It contains the stats for the lich and his traps. The digital text allows for easy reference during the complex final battle. The book also details the unique monsters of Chult. The PDF serves as a bestiary for the campaign. It also explains the “Death Curse” mechanics. The digital guide helps the DM enforce the time limit, adding tension to every decision. It is the must-have resource for running this legendary adventure.

The anthropomorphic characters in Orwell’s tale are not just animals; they are representations of different segments of society. The sheep who blindly repeat slogans, the skeptical donkey Benjamin, and the vicious dogs all play roles that we recognize in the real world. Secure a copy of the Animal Farm PDF to explore these character archetypes in depth. Orwell challenges us to ask ourselves which animal we would be in such a situation, making the reading experience deeply personal and introspective. https://animalfarmpdf.store/ Animal Farm Epub English

Mark Twain’s tale of a young boy’s life is a story that never grows old. The Adventures of Tom Sawyer is filled with excitement and heart. We provide a digital text that is perfect for reading on tablets and smartphones. Our version is clean and easy to navigate. With a Tom Sawyer PDF, you can take the story with you wherever you go, making it easy to escape into the world of St. Petersburg. https://tomsawyerpdf.store/ Tom Sawyer Full Text Pdf

Why do we still read The Awakening? Because it tells the truth about the human heart. If you want to read something real, search for the awakening pdf. The emotions are authentic, the characters are flawed, and the ending is inevitable. It is the antithesis of a fairy tale. A digital copy puts this raw, honest story at your fingertips. https://theawakeningpdf.store/ The Awakening Quiz Pdf

Il Crazy Time Casino Slot e un gioco d’azzardo molto conosciuto in Italia. Questo gioco e caratterizzato da una grafica molto dettagliata e da una varieta di funzioni bonus Questo gioco e caratterizzato da una grafica molto colorata e da una varieta di funzioni bonus . I giocatori possono scegliere tra diverse opzioni di scommessa I giocatori possono scegliere tra diverse combinazioni di scommessa .

live crazy [url=https://agosto.in/?p=74598]https://agosto.in/?p=74598/[/url]

Il Crazy Time Casino Slot e un gioco molto emotivo Il Crazy Time Casino Slot e un gioco molto coinvolgente . I giocatori possono vincere premi molto alti I giocatori possono vincere premi molto sostanziali . Il gioco e disponibile su diverse piattaforme Il gioco e disponibile su diverse piattaforme di gioco .

Il Crazy Time Casino Slot e una scelta eccellente per chi cerca un’esperienza di gioco unica . I giocatori possono scegliere tra una vasta gamma di giochi, inclusi slot, tavoli e giochi dal vivo. Il Crazy Time Casino Slot presenta una grafica incredibile e un’atmosfera di gioco coinvolgente . Inoltre, il casino online offre anche una serie di promozioni e bonus per attirare nuovi giocatori e premiare quelli esistenti.

Il Crazy Time Casino Slot e un gioco molto popolare in Italia, grazie alla sua semplicita e alla possibilita di vincere jackpot sostanziosi. Il gioco e facile da imparare e offre una grande varieta di opzioni di scommessa . I giocatori possono scegliere di giocare con soldi reali o di provare il gioco in modalita demo. Il gioco in modalita demo e una scelta eccellente per chi vuole familiarizzare con il gioco .

crazy time watch live [url=http://www.chiropractorcpt.com/crazy-time-live-casino-italia-risultati-crazy-time-in-diretta/]https://chiropractorcpt.com/crazy-time-live-casino-italia-risultati-crazy-time-in-diretta/[/url]

Il Crazy Time Casino Slot e un gioco da casino molto seguito in Italia. Questo gioco e stato creato per offrire ai giocatori un’esperienza di gioco unica e emozionante Questo gioco e stato realizzato per offrire ai giocatori un’esperienza di gioco divertente e appagante. I giocatori possono scegliere tra diverse opzioni di scommessa e vincere premi in denaro I giocatori possono scegliere tra diverse opzioni di scommessa e vincere premi in bonus .

crazy time studio [url=https://www.crazy-time-demo.com]https://crazy-time-demo.com/[/url]

Il Crazy Time Casino Slot e caratterizzato da una grafica di alta qualita e da un suono emozionante Il Crazy Time Casino Slot e caratterizzato da una grafica di alta tecnologia e da un suono stimolante. I giocatori possono giocare al Crazy Time Casino Slot su diversi dispositivi, tra cui computer, tablet e smartphone I giocatori possono giocare al Crazy Time Casino Slot su diversi dispositivi, tra cui desktop, tablet e apparecchi mobili.

“Если вы ищете полезный [url=https://seoblog360.ru/]SEO блог о продвижении сайтов[/url], то этот ресурс станет вашим надежным помощником в изучении и применении SEO-стратегий.”

Оптимальный вариант — тема, сочетающая популярность и низкую конкуренцию. Это позволит быстрее выйти в топ поисковиков. Изучите конкурентов, чтобы определить их слабые места.

Не менее важно учитывать свою экспертность в выбранной области. Если вы разбираетесь в теме, контент будет более качественным.

#### **2. Оптимизация контента под поисковые системы**

SEO-оптимизация — ключевой фактор продвижения блога. Используйте LSI-слова для естественного вхождения ключей. Также важно работать с метатегами. Оптимизированные заголовки увеличивают CTR.

Структура текста тоже играет роль. Используйте списки и таблицы для удобства чтения.

#### **3. Продвижение и привлечение трафика**

Без продвижения даже качественный контент останется незамеченным. Ведите email-рассылку, чтобы удерживать читателей.

Еще один эффективный метод — внутренняя перелинковка. Это также помогает равномерно распределять вес между страницами.

#### **4. Монетизация SEO блога**

Когда блог набирает трафик, можно задуматься о заработке. Контекстная реклама (AdSense, РСЯ) — простой способ монетизации.

Дополнительные возможности включают инфопродукты. Электронные книги и вебинары могут стать стабильным источником дохода.

—

#### **1. Выбор ниши для SEO блога**

Личный опыт поможет создавать уникальные и полезные материалы.

#### **2. Оптимизация контента под поисковые системы**

Короткие предложения и четкие формулировки улучшают восприятие.

#### **3. Продвижение и привлечение трафика**

Гостевые посты на авторитетных сайтах помогут получить ссылки.

#### **4. Монетизация SEO блога**

Партнерские программы приносят доход за продажи товаров.

con la crescente popolarita dei casino online . I giocatori italiani possono ora accedere a una vasta gamma di giochi, compresi i classici slot . La slot machine Crazy Time e una delle piu popolari, con la collaborazione di designer e sviluppatori.

La sua popolarita e dovuta alla sua semplicita e divertimento . I giocatori possono scegliere tra vari livelli di difficolta . La slot machine Crazy Time e una delle piu conosciute tra i giocatori esperti.

crazy time live casino [url=https://lokpatrika.in/uncategorized/crazy-time-live-italia-casino-online-gioca-con-soldi-veri/]https://lokpatrika.in/uncategorized/crazy-time-live-italia-casino-online-gioca-con-soldi-veri/[/url]

Check out my latest gallery, it’s my dirtiest one yet. – https://telegra.ph/Enter-01-31?async

Il gioco d’azzardo e un fenomeno sempre piu diffuso in Italia, grazie alla possibilita di giocare online. I giochi da casino sono diventati sempre piu popolari tra gli italiani, che possono ora scegliere tra una vasta gamma di opzioni . Il Crazy Time Casino Slot e un gioco da casino che sta guadagnando sempre piu popolarita in Italia, grazie alla sua originalita e ai suoi premi .

risultati live crazy time [url=https://demoforme.com/?p=126333/]risultati live crazy time[/url].

Il gioco offre una grafica di alta qualita e un’atmosfera emozionante, che lo rendono un’esperienza di gioco unica . I giocatori possono godere di un’esperienza di gioco emozionante e interattiva, grazie alle funzionalita del gioco . Il gioco e una scelta ideale per chi cerca un’esperienza di gioco emozionante e divertente.

Ultimately, this is a story about identity. Jenny Han asks who we are when we are not defined by others. The search for the PDF leads to this central question. “The Summer I Turned Pretty” is about Belly defining herself. It is a journey worth taking. It is a brilliant start to a trilogy.

grazie alla grande varieta di opzioni disponibili . Il Crazy Time Casino Slot e uno dei giochi piu amati e giocati in Italia, e per la possibilita di vincere grandi premi. I giocatori italiani possono scegliere tra una vasta gamma di slot machine online, e con grafiche e suoni di alta qualita.

crazy time bonus [url=https://www.thegoldenalbatross.com/crazy-time-live-casino-online-gioca-con-soldi-veri-in-diretta/]https://thegoldenalbatross.com/crazy-time-live-casino-online-gioca-con-soldi-veri-in-diretta/[/url]

Il Crazy Time Casino Slot e un gioco molto popolare e per la sua disponibilita su molte piattaforme di gioco online. I giocatori possono giocare a questo gioco utilizzando il loro computer o dispositivo mobile .

Cousins Beach is where Belly leaves her real life behind. Jenny Han captures the escapism of summer perfectly. Accessing the story via PDF is convenient for modern readers. “The Summer I Turned Pretty” is a book about the defining moments of youth. It is about the first heartbreak and the first real kiss. The emotions are heightened by the setting and the season. It is a beautifully written young adult novel. https://thesummeriturnedprettypdf.site/ The Summer I Turned Pretty Book Download Epub

When Belly turns pretty, the world tilts on its axis. Jenny Han describes this disorientation perfectly. If you are hunting for the PDF of this book, you are in for an emotional ride. The dynamics at the summer house are fraught with new tension. Conrad is distant, Jeremiah is playful, and Belly is confused. It is a classic setup executed with modern sensibilities. The story is a reminder of how intense and all-consuming first love can be. https://thesummeriturnedprettypdf.site/ The Summer I Turner Pretty Pdf

Nostalgia is a powerful drug, and this book is full of it. Jenny Han taps into our collective memories of summer. Searching for “The Summer I Turned Pretty PDF” is a way to access that feeling. The story is about the innocence of childhood giving way to the experience of adolescence. It is a bittersweet transition. The book handles it with care and empathy. It is a beautiful story. https://thesummeriturnedprettypdf.site/ The Summer I Turnes Pretty Pdf

The novel is a masterclass in irony. Austen says one thing but means another. To catch the irony, you need to be sharp. A digital text allows you to reread and catch the double meanings. If you are looking for a Pride and Prejudice PDF, you enjoy intellectual stimulation. Our site is dedicated to the cleverness of the book. Sharpen your wits with Jane Austen.

This novel is a love letter to the rom-com genre, referencing classics while carving out its own space in the hearts of readers. Liz Buxbaum is a relatable heroine whose flaws make her lovable, and Wes Bennett is the boy next door of dreams. Accessing the story via a PDF or digital reader is a popular choice for those who want to carry the magic of this book everywhere. It is a narrative that teaches us that while we cannot script our lives, the improvisation is often where the true magic happens.

For language lovers, the prose style of Emily Brontë is a delight. A Wuthering Heights PDF showcases her poetic command of English. The descriptions are lush and rhythmic, often resembling poetry more than prose. Having the text in a digital format allows you to highlight your favorite sentences and save them. It is a book that celebrates the beauty of language, even when describing ugly emotions. The digital version is a treasury of words that aspiring writers and avid readers will appreciate for its stylistic brilliance.

Gardiner is the name of the sensible relatives who help Elizabeth. They represent a middle-class ideal. To see their role, you need the text. A digital copy highlights their importance. Searching for a Pride and Prejudice PDF reveals the different social strata. Our website focuses on the class distinctions in the novel. See how the merchant class saves the day.

Ultimately, East of Eden is about the possibility of redemption. No matter what you have done, you have the choice to be good. It is a hopeful message. In difficult times, this book is a balm for the soul. Finding an East of Eden PDF can be the start of a healing journey. Our platform focuses on the uplifting messages within the text, providing daily quotes and affirmations derived from the book. We focus on the light that shines through the darkness of the story.

This novel is a treasure trove of romantic moments and witty comebacks. Liz and Wes are a pair for the ages. A digital PDF copy is a modern way to enjoy this timeless story. It is a narrative that encourages us to stop watching life from the sidelines and start living our own better-than-the-movies adventure.

Step into a world where prom proposals and parking spot wars lead to true love. Lynn Painter weaves a narrative that is as comforting as a warm blanket and as exciting as a first kiss. If you are tech-savvy, grabbing a Better Than the Movies PDF is the quickest way to meet Liz and Wes. Their story is a masterclass in the fake-dating trope, providing plenty of swoon-worthy moments that will make you wish the book would never end.

For those interested in the craft of writing, East of Eden serves as a masterclass in character development and setting the scene. Steinbeck’s journals, written while he was drafting the book, reveal his struggles. Comparing the final text to his journals is a fascinating exercise. Writers often look for an East of Eden PDF to study the sentence flow and structure. Our site offers a writer’s perspective on the novel, breaking down the techniques Steinbeck used to build tension and empathy. We help aspiring writers learn from the master.

This is the ultimate comfort read for anyone who loves love. The progression from enemies to friends to lovers is handled with expert care. If you are looking for a Better Than the Movies PDF, you are in for a treat with this heartwarming file. It is a book that teaches us that we are the directors of our own lives, and the unscripted moments are usually the best parts.

The dialogue in this book is sharp, modern, and full of personality. You will find yourself laughing out loud at Liz and Wes’s exchanges. Finding a PDF version allows you to keep this source of joy with you at all times. It is a story that reminds us that the person who annoys us the most might just be the one who knows us the best, making for a love story better than the movies. https://betterthanthemoviespdf.site/ Better Than The Movies Pdf Free Online

The intricate plotting of the novel ensures that no detail is wasted. Events in the first chapter resonate in the last. It is a tightly woven net of cause and effect. Mystery fans will appreciate the slow reveal of secrets. An East of Eden PDF allows for easy backtracking to check clues and foreshadowing. Our content highlights these narrative threads, showing how masterfully Steinbeck constructed the plot. We help you appreciate the architectural genius of the novel’s structure. https://eastofedenpdf.site/ East Of Eden By John Steinbeck Free Download Pdf

This book is a delightful romp through the ups and downs of high school romance. Lynn Painter has a gift for writing dialogue that sounds authentic and incredibly funny. For those who prefer screen reading, finding a Better Than the Movies PDF is the key to unlocking this gem. The story of Liz and Wes is a reminder that sometimes the person you are looking for has been right there all along, waiting for the script to change. https://betterthanthemoviespdf.site/ Better Than The Movies Pdf Download Free

If you are a fan of enemies-to-lovers, this is the gold standard. The pranks and the bickering only make the romance sweeter. A PDF version is perfect for reading during those stolen moments in your day. It is a book that delivers exactly what it promises: a romance that outshines the silver screen. https://betterthanthemoviespdf.site/ Better Than The Movies Book Online Free Pdf

The book is a critique of the “civilizing” influence of society. A Wuthering Heights PDF shows how the refinement of the Lintons weakens the spirit, while the wildness of the Earnshaws destroys it. The text explores the middle ground. The digital reader allows you to highlight the contrasts between the raw and the cooked, the wild and the tame. It is a thematic deep dive that is facilitated by the tools of the digital age. Explore the savage nobility of the moors through your screen. https://wutheringheightspdf.site/ Read Wuthering Heights Pdf

The humor in the book, largely provided by the Hamilton family, balances the darkness of the Trask storyline. Samuel’s inventions and Irish wit are delightful. It is not all doom and gloom. Readers looking for a balanced narrative will enjoy this mix. An East of Eden PDF is great for reading the lighter chapters when you need a break. Our site highlights the humorous and heartwarming moments, reminding readers that there is joy in the Salinas Valley as well. We provide a holistic view of the emotional spectrum of the novel. https://eastofedenpdf.site/ Eden Of The East First Mobie

يُعتبر موقع betfinal واحدًا من المواقع الرائدة في مجال المراهنات الرياضية . يمكنهم também الوصول إلى مجموعة متكاملة من المراهنات علي ألعاب الكازينو. موقع betfinal يُعتبر خيارًا رائعًا لجميع عشاق المراهنات الرياضية .

يمكنهم أيضًا الاستفادة من الدعم الفني المتوفر على مدار الساعة . يتمتع موقع betfinal بسمعة طيبة في مجال المراهنات الرياضية . موقع betfinal يُعتبر خيارًا مثاليًا للمراهنين الرياضيين .

يتميز موقع betfinal بوجود مجموعة واسعة من الألعاب الرياضية . حيث يمكنهم أيضاً الوصول إلى مجموعة متكاملة من المراهنات الرياضية. يتمتع موقع betfinal بسمعة طيبة في مجال المراهنات الرياضية .

يمكنهم أيضاً الاستفادة من مجموعة متنوعة من الخدمات . يُعتبر موقع betfinal خيارًا رائعًا لجميع عشاق المراهنات الرياضية . حيث يمكنهم أيضاً الوصول إلى خدمات دعم فني ممتازة.

يمكن للمستخدمين الاستمتاع بسهولة الوصول إلى موقع betfinal . حيث يوفر فرصًا لتحقيق الأرباح . موقع betfinal يُعتبر خيارًا مثاليًا للمراهنين الرياضيين .

بيت فاينل مصر [url=http://www.marsdbh.com/]https://marsdbh.com/[/url]

منصة 888starz معروفة بمنحها للجوائز الكبيرة . يمكن لل玩idores Anastasia أن يحصلوا على المساعدة التي يحتاجونها على منصة 888starz. اللاعبون يمكن أن يلعبوا بألعاب الروليت والبل랙 جاك الرائعة . 888starz توفر مجموعة واسعة من الألعاب الرائعة .

تحميل 888starz [url=https://888starz-egypteg.com/apk/]تحميل 888starz[/url]

Sometimes the best stories are the ones that have been told for centuries. There is a reason this book has never been out of print. To find out why, you must read it yourself. A digital version ensures it is always available. Searching for a Pride and Prejudice PDF leads to a discovery of quality. Our website champions the classics. readability and accessibility are our goals for this timeless tale. https://prideandprejudicepdf.site/ Hardly Incite Sister Affection Pride And Prejudice Pdf

Students analyzing the role of women in the 19th century will find a wealth of material in this text. A Wuthering Heights PDF allows for a focused study of Catherine Earnshaw and her daughter. Their struggles against the patriarchal constraints of their society are central to the plot. By using the search function of a digital reader, you can collate instances of female agency and oppression within the novel. This makes the drafting of essays on gender themes much more efficient, allowing for a deeper engagement with the social critique embedded in the story. https://wutheringheightspdf.site/ Emily Bronte Wuthering Heights Summary Pdf

Steinbeck’s use of biblical names – Adam, Charles (Cain), Aron (Abel), Cal (Cain) – is a puzzle waiting to be solved. It telegraphs the characters’ roles. Decoding these names is part of the fun. An East of Eden PDF makes it easy to track these character arcs. Our platform offers a guide to the onomastics (study of names) in the book, explaining the significance of every choice Steinbeck made. We reveal the hidden layers of meaning in the character names. https://eastofedenpdf.site/ East Of Eden The Movie Pdf

Why settle for a two-hour film when you can immerse yourself in hours of reading bliss with Lynn Painter’s acclaimed novel? The banter between the protagonist and her love interest is sharp, witty, and full of underlying tension. Readers worldwide are eager to get their hands on a Better Than the Movies PDF to join the conversation about this trending title. It serves as a reminder that the best romantic leads are often the ones who challenge us, annoy us, and ultimately understand us better than anyone else. https://betterthanthemoviespdf.site/ Pdf Of Better Than The Movies

Steinbeck’s descriptions of the mechanics of early automobiles are surprisingly detailed and entertaining. It shows the march of progress disrupting the quiet valley life. Tech history enthusiasts will get a kick out of these passages. An East of Eden PDF allows you to quickly find the “car chapters.” Our site explains the historical context of this technological revolution, showing how it symbolizes the coming changes in the characters’ lives. We connect the industrial history with the personal narratives. https://eastofedenpdf.site/ East Of Eden Steinbeck Epub

The chemistry between the leads is undeniable, even on the page. The sparks fly from their first meeting. To feel the heat, you need to read the words. A digital format captures this energy. If you are looking for a Pride and Prejudice PDF, you are looking for passion. Our platform champions the romance of the novel. Experience the love story that set the bar for all others. https://prideandprejudicepdf.site/ Pride And Prejudice Great Illustrated Classics Pdf

There is a raw, primal energy to the love expressed in this novel that is unlike anything else in Victorian literature. If you want to feel that power, find a Wuthering Heights PDF. The characters do not just love; they consume one another. It is a depiction of passion that borders on madness. Reading this on a digital device is a private, intense experience. You can carry the emotional weight of the story in your pocket, ready to dive back into the turbulent world of the moors whenever you need an escape from the mundane. https://wutheringheightspdf.site/ Wuthering Heights Themes Pdf

For those who prioritize accessibility, the digital format is a blessing. A Queen of Shadows pdf makes the book available to everyone, everywhere. It breaks down barriers to entry. You can read it on your phone during a lunch break or on a tablet in bed. The story is always with you. It adapts to your lifestyle. It is the modern way to experience an epic legend.

The significance of the number 124 in the novel is immediate. A Beloved PDF helps readers track the house’s evolution. It starts spiteful, becomes loud, and ends quiet. A digital version allows for a quick review of the chapter openings that signal these shifts, serving as a structural guide to the emotional phases of the narrative. It helps the reader orient themselves in the turbulent emotional landscape that the characters inhabit.

The evolution of Aedion Ashryver from a prisoner to a key general in Aelin’s army is a highlight of the story. His unwavering loyalty to his queen and his cousin is moving to witness. Many fans search for the Queen of Shadows pdf to read his scenes specifically. His relationship with Lysandra also begins to take root here, offering a glimpse of future developments. The book handles the logistics of war – supply lines, morale, and leadership – surprisingly well for a fantasy novel, adding a layer of realism to the epic conflict.

The contrast between the “jungle” white folks planted in black folks and the real nature is a profound metaphor. To unpack this, a Beloved PDF is essential. Morrison argues that the savagery attributed to the slaves was actually a projection of the masters. A digital text allows for a careful examination of this complex passage, which critiques the projection of fear and violence onto the oppressed. It’s a critical section for understanding the novel’s stance on racism and nature.

This is the crescendo of a symphony that started in a salt mine. The music of the story reaches its loudest point. Listen to the story in the kingdom of ash pdf. It is a masterpiece of composition.

For those interested in the intersection of history and gothic fiction, this novel provides a masterclass in atmosphere. A Beloved PDF is frequently sought after by readers who want to analyze the gothic elements of the story, from the malevolent ghost to the dark secrets of Sweet Home. The psychological depth of Sethe’s character offers endless material for discussion. Digital access to the text makes it easier to reference the flashbacks that explain why Sethe made the unthinkable choice that defines her existence. https://belovedpdf.site/ Beloved Analysis Pdf

Sarah J. Maas creates a world where women are the primary movers and shakers. From Aelin to Manon to Lysandra, the female characters drive the plot. A Queen of Shadows pdf is a showcase of diverse female strength. They are warriors, queens, witches, and courtesans, and they are all formidable. This representation is refreshing and empowering. It challenges gender norms within the fantasy genre and offers a variety of role models for readers. https://queenofshadowspdf.site/ Queen Of Shadows Pdf Download Free

The journey south in The Road is one of the most harrowing treks in literary history. Cormac McCarthy strips away civilization to reveal the raw core of humanity, oscillating between absolute brutality and tender affection. The story follows two survivors navigating a world covered in ash, where the sky is permanently gray and the cold is unrelenting. For students and book clubs, having access to the text in a portable format is essential for discussion. Whether you are reading a physical copy or searching for the road pdf to read on your tablet, the experience of accompanying these characters through their desolate reality is unforgettable and life-changing. https://theroadpdf.site/ Pdf Of The Road By Cormac Mccarthy

Ultimately, this is a story about home. Fighting for it, dying for it, and returning to it. The emotional core is universal. Find your way home with the kingdom of ash pdf. It is a journey you will never regret taking. https://kingdomofashpdf.site/ Read Kingdom Of Ash Online Pdf

The Road is a novel of few words but deep meaning. McCarthy’s prose is efficient and evocative. The father and son’s journey is a universal story. This book won the Pulitzer Prize. If you are a fan of literature, finding the road pdf is a must. It is a story that explores the essence of humanity. https://theroadpdf.site/ The Road By Cormac Mccarthy Online Pdf

Why did Lydia die? That is the question that haunts the police, her parents, and her siblings. But the reader soon learns that the mystery is not just about the final act, but the years leading up to it. If you want to uncover the truth, you might be looking for a copy of the book or the Everything I Never Told You PDF. The digital format is perfect for annotating the many poignant passages found within. It is a story of profound grief and the slow, painful process of healing that can only begin once the truth is revealed.

Ultimately, Mockingjay is a plea for peace. It shows the ugly face of war so that we might avoid it. The message is vital for every generation. Keep this message alive by reading the Mockingjay PDF. The digital format ensures the book is accessible to a global audience. It is a story that needs to be read, shared, and remembered.

Friendship and loyalty are tested as the squad faces death at every turn. Characters like Finnick and unexpected allies play pivotal roles in the endgame. Ensure you have the Mockingjay PDF to follow every twist and turn of their journey. The digital file is durable and portable, unlike paper pages that can tear or fade. The bonds formed in the arena and the bunker are the only things holding the rebels together. It is a celebration of the family we choose. https://mockingjaypdf.site/ Mockingjay Suzanne Collins Epub

The contrast between the lavish meals of the Capitol and the starvation in the districts is a recurring motif. In Mockingjay, the tables turn, and the Capitol citizens taste fear and scarcity. A Mockingjay PDF allows you to digest this heavy symbolism at your own pace. The digital format allows for easy pausing and resuming, perfect for a busy lifestyle. The social commentary is woven naturally into the plot. It is a book that feeds the mind and the soul. https://mockingjaypdf.site/ Mockingjay Pdf Indonesia

When you gaze into the abyss, the abyss gazes back. Zade is the abyss. Adeline is the one gazing. If you are looking for the Haunting Adeline PDF, you are gazing too. The book is a profound exploration of the human condition. It is a story that is both terrifying and beautiful. It is a novel that you will never forget. https://hauntingadelinepdf.site/ Haunting Adeline Epub Gratis

Lydia is dead, but they don’t know this yet. This chilling opening line sets the stage for Celeste Ng’s debut novel, a profound mystery about the Lee family in 1970s Ohio. As the family grapples with the sudden loss of their favorite child, deep-rooted secrets begin to surface. If you are searching for Everything I Never Told You, perhaps hoping to find a PDF to read on your tablet or computer, you are about to enter a world of complex family dynamics. The story weaves through the burden of parental expectations and the isolation of being different. It is a narrative that demands to be read, whether in a physical book or a digital format. https://everythinginevertoldyoupdf.site/ Everything I Never Told You Novel Pdf Download

Concludere la Century Trilogy è un dovere per ogni appassionato di Ken Follett, e I giorni dell’eternità non delude. Le oltre mille pagine volano via veloci grazie al ritmo incalzante della narrazione. Se optate per l’epub, avrete il vantaggio di una lettura ergonomica e sempre disponibile. Rivivrete i momenti salienti del tardo Novecento attraverso gli occhi di personaggi che avete imparato ad amare. È un’opera che lascia il segno, perfetta per essere letta e riletta in formato digitale.

Un mistero profondo in “L’ultimo segreto”. Robert Langdon indaga. La versione pdf è ideale. La storia è ricca di colpi di scena. Se ami i thriller, non puoi perdere questo libro.

Un viaggio letterario che è anche un viaggio visivo, grazie agli acquerelli dell’autore che sono parte integrante e inscindibile della narrazione e del suo fascino. Anche nelle versioni digitali cercate come il piccolo principe pdf, le immagini giocano un ruolo fondamentale nel trasmettere le emozioni del racconto. La storia ci insegna a dare valore ai riti, quei momenti che rendono un giorno diverso dagli altri e un’ora diversa dalle altre, sottolineando l’importanza di creare abitudini condivise che rafforzano i legami affettivi.

La ricerca della conoscenza può essere fatale. “L’ultimo segreto” ci mostra quanto può essere pericoloso sapere troppo. Robert Langdon è il nostro Virgilio in questo inferno di codici e complotti. La versione pdf è l’ideale per chi vuole avere il libro sempre con sé. L’autore costruisce una storia che ti prende allo stomaco e non ti lascia più. Scopri il mistero che sta facendo tremare i potenti del mondo.

Ogni capitolo di questo libro è un tassello di un mosaico doloroso e bellissimo. Una vita come tante è il romanzo che ti accompagna per settimane. Cercare la versione PDF o eBook ti permette di avere sempre accesso a questa storia incredibile. La Yanagihara ha la capacità rara di rendere reali i suoi personaggi, facendoti soffrire e gioire con loro. Scegli la lettura digitale per immergerti completamente nelle atmosfere del libro, ovunque ti trovi. Un’opera che non può mancare nella libreria virtuale di ogni lettore.

La trilogia del secolo non poteva finire in modo migliore. I giorni dell’eternità è un romanzo potente, ricco di sfumature e di verità storiche. Leggerlo in epub vi darà la possibilità di apprezzare la complessità della trama ovunque voi siate. Ken Follett riesce a rendere avvincente anche la politica più intricata, mescolandola con le vicende umane dei suoi personaggi. È un libro che vi accompagnerà per giorni, offrendovi spunti di riflessione e momenti di puro intrattenimento, il tutto racchiuso nel vostro dispositivo portatile. https://igiornidelleternitaepub.site/ I Giorni Dell’eternita Pdf Gratis

Sei alla ricerca di una storia che ti rimanga dentro per sempre? Una vita come tante è la risposta. La ricerca di un PDF o di una copia digitale dimostra la voglia di confrontarsi con questo gigante della letteratura. Hanya Yanagihara ha creato un personaggio, Jude, che è impossibile non amare e compatire. Leggere su un dispositivo elettronico ti permette di affrontare la lunghezza del libro con agilità, senza perdere nulla della profondità del testo. Non esitare a iniziare questo viaggio letterario che ha commosso milioni di persone. https://unavitacometantepdf.site/ Una Vita Come Tante Di Hanya Yanagihara

Sei appassionato di enigmi storici e thriller mozzafiato? “L’ultimo segreto” è il libro che stavi aspettando. Robert Langdon torna per svelare un mistero che ha radici profonde nel tempo. La versione pdf offre la massima flessibilità per chi ama leggere in movimento. L’autore crea un’atmosfera unica, dove la cultura si mescola all’azione pura. Ogni pagina è una sfida all’intelligenza del lettore. Unisciti alla ricerca della verità e preparati a scoprire cosa si nasconde dietro l’ultimo, grande segreto. https://lultimosegretopdf.site/ L’ultimo Segreto Dan Brown Download

Non si è mai troppo grandi per lasciarsi affascinare dalla storia di un bambino che chiede di disegnargli una pecora, un incipit che apre le porte a un mondo di immaginazione senza limiti. La ricerca di formati accessibili come il piccolo principe pdf testimonia la vitalità di un’opera che, a decenni dalla sua pubblicazione, non ha perso un grammo della sua forza evocativa. È un invito a prendersi cura del proprio pianeta interiore, a strappare i baobab prima che diventino troppo grandi e a proteggere la propria rosa, metafore di una disciplina spirituale necessaria per vivere bene. https://ilpiccoloprincipepdf.site/ Il Piccolo Principe È La Volpe Testo Pdf

If you are a visual learner, seeing the words on the page is crucial. Listening is great, but reading solidifies spelling and grammar. A short stories in German PDF can help, but a formatted book is easier to read and navigate. The clear layout of “Short Stories in German for Beginners” reduces eye strain and mental fatigue. You can focus entirely on the content. The experience of reading a well-designed book enhances your ability to concentrate and absorb the material. Give your eyes and your brain a treat with this excellent resource.

La sortie de ce livre a provoqué une onde de choc, et pour cause : c’est un règlement de comptes littéraire de haute volée. Si vous appréciez les essais politiques, téléchargez l’epub pour lire le journal d’un prisonnier sans attendre. Nicolas Sarkozy y fait preuve d’une lucidité redoutable sur son propre sort et sur l’état de la justice en France. C’est un livre qui se dévore, page après page, tant la tension narrative est palpable.

Dans le monde de Freida McFadden, personne n’est innocent et tout le monde a quelque chose à cacher. “Le Boyfriend” est l’exemple parfait de ce style unique qui mêle angoisse et curiosité. Ce livre en format epub est idéal pour une lecture nomade et passionnante. L’histoire vous prend à la gorge et ne vous lâche plus. Si vous aimez les thrillers qui vous retournent le cerveau, vous allez adorer ce roman. C’est une plongée fascinante dans les méandres du mensonge et de la manipulation amoureuse.

The humor in Better Than the Prom is sharp and observational. It pokes fun at the absurdities of high school life. If you are looking for the PDF, you are looking for a laugh. The book is genuinely funny. It uses humor to diffuse tension and build character.

As you advance in German, you need to encounter words in different contexts to truly understand them. A single short stories in German PDF might show a word once. This collection, with its variety of genres, ensures you see how language is flexible. You see how a word is used in a crime scene versus a historical setting. This depth of knowledge is what separates beginners from intermediate speakers. Deepen your understanding of German through the diverse contexts provided in these stories.

Découvrez le dernier ouvrage percutant de l’ancien président, une plongée intime dans ses réflexions face à l’adversité judiciaire. Le journal d’un prisonnier de Nicolas Sarkozy offre une perspective inédite sur les épreuves traversées par l’homme d’État. Pour les amateurs de lecture numérique, trouver ce récit en format epub permet une immersion immédiate dans ses pensées les plus secrètes. C’est un témoignage brut qui interroge sur le fonctionnement de la justice et la résilience nécessaire pour survivre aux tempêtes médiatiques et politiques qui ont secoué la France ces dernières années.

The “enemies to lovers” trope gets a fresh update in this delightful novel. Liz and Wes have a history that adds weight to every interaction. If you are looking for the Better Than the Prom PDF, you are in for a ride filled with emotional highs and lows. The book explores the vulnerability required to let someone in, especially when you have built walls against them. It is a touching story that is perfect for fans of contemporary romance.

L’angoisse est au rendez-vous avec “Le Boyfriend”. Ce roman de Freida McFadden est un modèle du genre thriller domestique. Disponible en téléchargement epub, c’est le livre qu’il vous faut pour vos soirées. L’intrigue est menée de main de maître, avec des twists qui vous laisseront pantois. C’est une histoire qui se dévore, pleine de suspense et de tension. Une lecture numérique à ne pas manquer.

High school senior Liz Rosen had the perfect prom night mapped out in her head, but reality had other plans. When her dream date flakes, she finds herself in a fake-dating scheme with Wes Bennett, the annoying neighbor she has sworn to hate. If you are searching for the Better Than the Prom PDF or a digital version to read on the go, you are in for a treat with this rom-com. It perfectly captures the chaos of senior year and the thin line between love and hate. Discover why this book is making waves among romance readers everywhere. https://betterthantheprompdf.site/ Better Than The Prom Free Download

German has a reputation for being difficult, but it doesn’t have to be. The complexity often comes from the way it is taught. If you look for a short stories in German PDF, you are seeking a more natural path. Reading stories allows you to absorb the logic of the language without analyzing it to death. You begin to anticipate word order and gender intuitively. This “language sense” is what leads to fluency. Give yourself the opportunity to develop it by immersing yourself in these carefully written beginner stories. https://shortstoriesingermanpdf.site/ Short Stories In German For Beginners In Berlin Libraries

La plume de Nicolas Sarkozy est connue pour son énergie, et elle ne faiblit pas dans cette épreuve. Ce récit est celui d’un homme qui refuse la fatalité. Pour les lecteurs nomades, la version epub constitue le moyen le plus simple d’accéder au contenu explosif du journal d’un prisonnier. L’auteur y décortique les accusations portées contre lui et livre sa version des faits avec une précision d’avocat. C’est un document brut, parfois émouvant, souvent révolté, qui éclaire les zones d’ombre de la justice. https://lejournaldunprisonnierepub.site/ Le Journal D’un Prisonnier